|

|||||||

| BEARINGS | ROLLER & WHEELS | ||||||

| Manufacturing process quality control |

How do we control quality ? |

|

|

| Review of bearing design | |

| Review of manufacturing plan | |

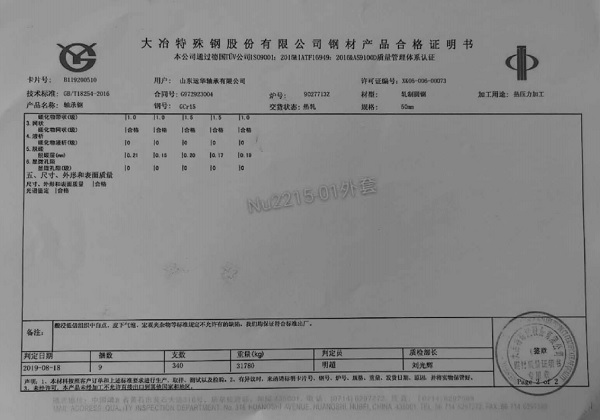

| Raw material quality control | |

| Spare part incoming quality control | |

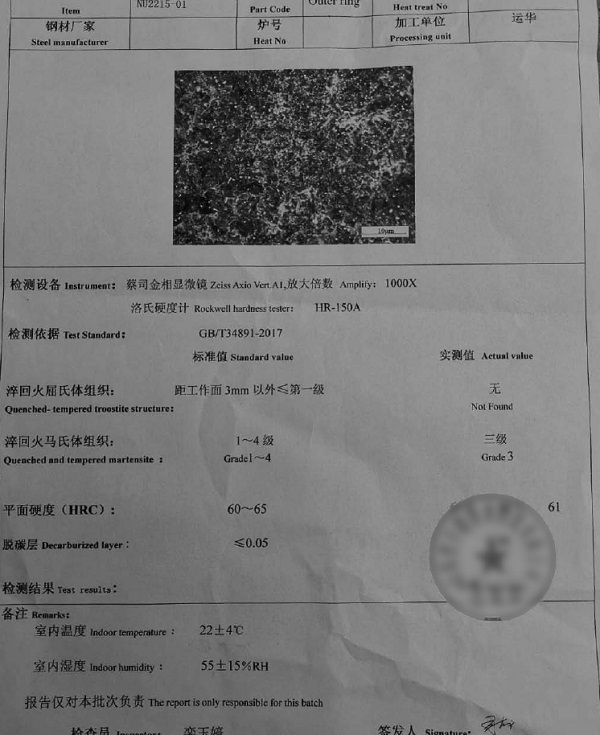

| Heat treatment quality control | |

| Turning and grinding tolerance control | |

| Assembly quality control | |

| Washing and pre-packing quality control | |

| Bearing spare part sorting and grouping | |

| Finish bearing inspections and sorting | |

| Bearing life span verification | |

| Non-manufacturing quality control | |

| Pre-load quality inspection and control | |

| After sales quality feedback | |

| Close loop quality control | |

|

Copyright reserved from 2020.1.1 to 2022.1.1

|

|